Overview

CFS-NextGenSteels is the shorthand name for the new project: Optimization and Application of Next Generation Steels in Construction with principal funding from the National Science Foundation (NSF), Engineering for Civil Infrastructure program within the Civil Mechanical and Manufacturing Innovation division of NSF under award IDs: #1760953.

This research aims to advance knowledge leading to buildings with sustainability and structural resilience, while maintaining economic efficiency and the competitiveness of domestic steel production, by advancing the application of next-generation steels into building construction. A large class of new, high-performance steels has been developed for automotive applications to great success, but various technical challenges must be overcome before these steels can be widely integrated into building construction. A potential application is cold-formed steel studs and joists in buildings that employ sheet steels with thicknesses similar to next generation automotive steels. The possible benefits of using these next-generation steels include more efficient material use and construction, and lower initial and life-cycle costs. These steels also offer the potential for structural engineers and architects to create novel solutions in design and construction.

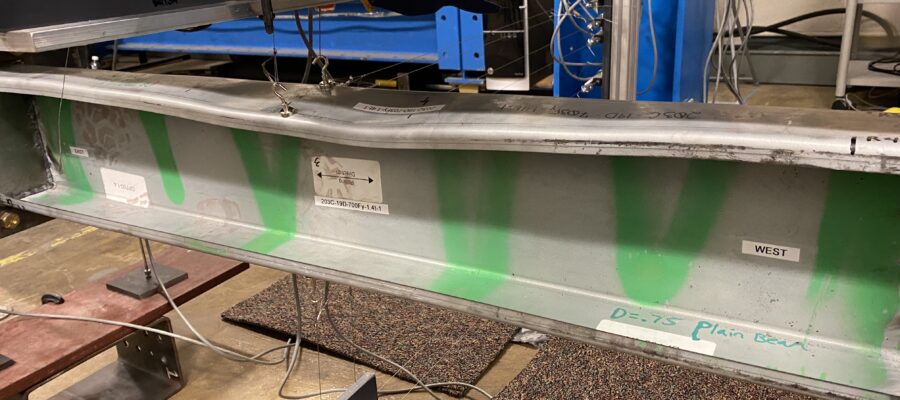

The objective of this research is to overcome the barriers in the application of next generation steels to cold-formed steel building construction and begin the optimization of the uses of these steels in this building system. Optimization and application of the use of next generation steels in cold-formed steel framing requires overcoming scientific barriers: generalized strength prediction of these uniquely strong but slender members is needed for engineering design, a deeper understanding of the material ductility that structural applications require is needed so that the new steels can be tailored to their demands at minimum cost, optimized shapes specific to construction applications are needed for efficiency, and prototyped solutions are needed to provide experimental evidence of superior performance. A series of targeted experiments at the material, connection, and member scale will be studied along with computational nonlinear collapse simulations and shape optimization to address the barriers to the adoption of next generation steel in construction.

Project team

The NSF project team consists of PIs Ben Schafer (JHU) and Zhanjie Li (SUNY-Poly). Also at JHU, Ph.D. student Chu Ding is working on the project. In addition, a unique collaboration has been established with CFSRC affiliated researcher Hannah Blum (UW-Madison) who is participating as a separately funded collaborator with her PhD student Yu Xia. Industry participants include the American Iron and Steel Institute, ClarkDietrich, and others.

Disclaimer

Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.